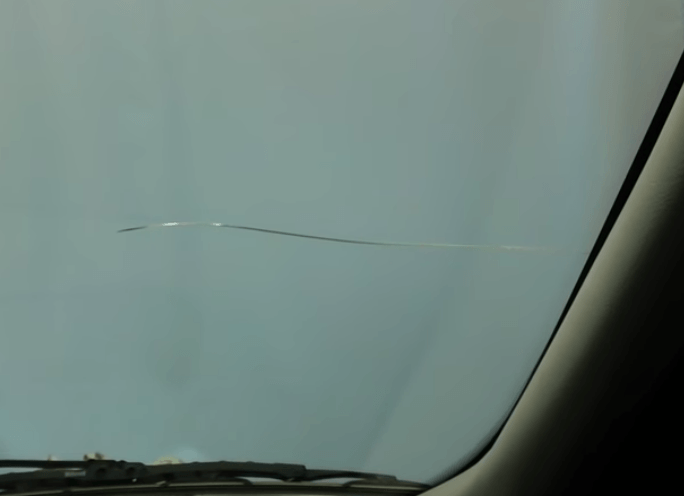

The windshield edge crack is a crack that forms because of manufacturing residual stress around the perimeter called the "Weak-Spot" or "Tension Bulge". This 2" area around the perimter fractures 3.5 times easier than the rest of the windshield. The other stress is calleld induced stress that happens when the windshield is installed. These are manufacturing defects and due-to-the-fact that these stresses are in the windshield, when an object like a pebble, strikes the windshield it causes these stresses to release the energy stored in the windshield, and thus a crack starting at the edge when there is so much as a pinhead size fracture in this weak-spot area.

90% of all windshield cracks that you will come across as a professional windshield repair technician will be the edge crack. The edge crack will run from the frit up to 14 inches long.

There are instances where you have longer cracks in the windshield up to 24 inches+, however, those are cracks that have grown overtime due to lack of a repair may not be repairable to due dust and dirt buildup in the crack.

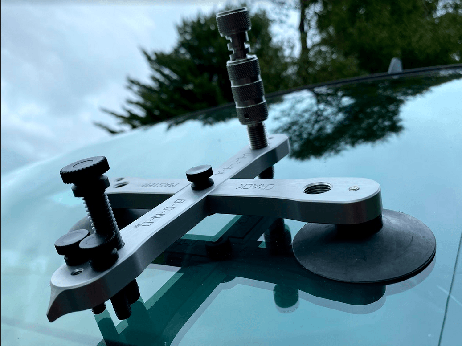

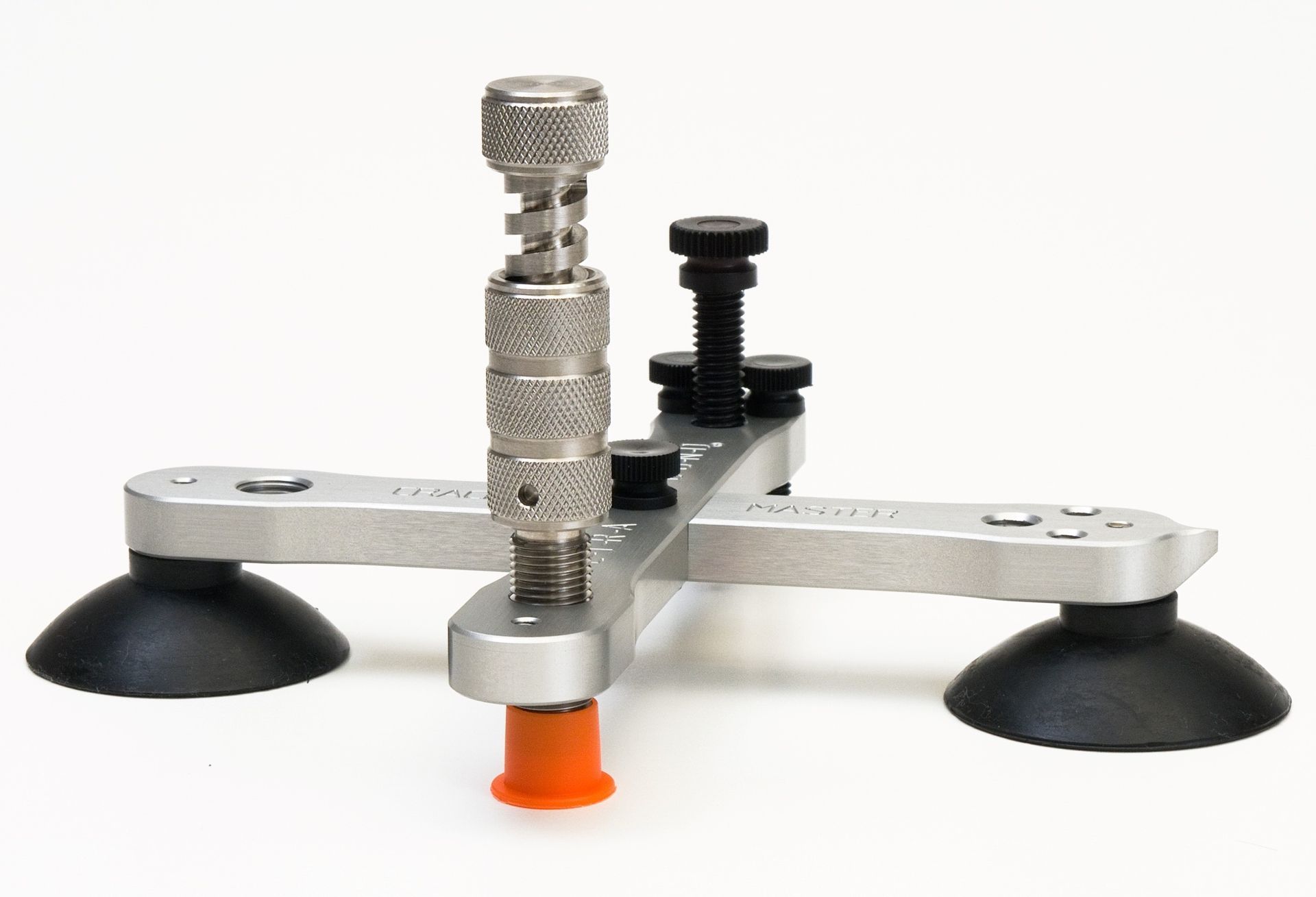

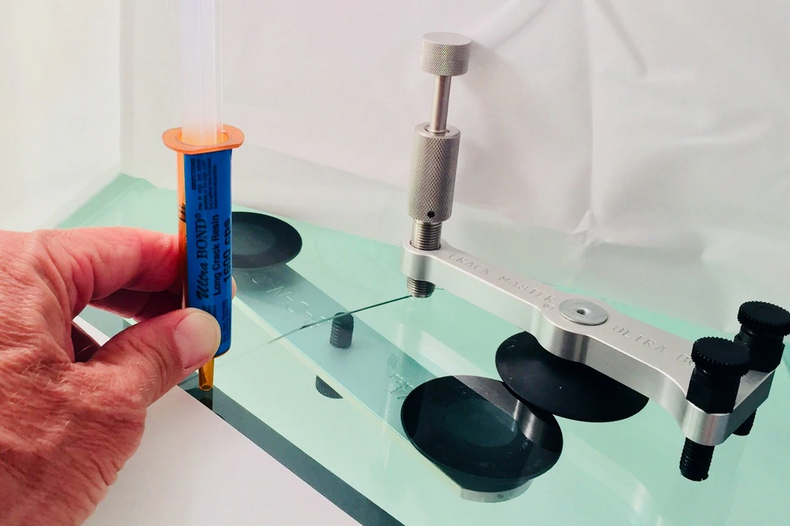

All edge cracks and long crack windshield repair will use a repair process called "Meet In The Middle" Windshield Crack Repair technique. This is repair process invented by the founder of Ultra Bond, Richard Campfield.

In the video above, you can watch a full on demo, with introductary information about the edge crack, understanding the edge crack, what causes it to crack, and the proper repair steps to restore the windshield to pre-factory loss conditon!